- Gwajin Tensile:Gwajin juzu'i yana ƙayyadaddun ƙarfin juzu'i, haɓakawa, da ma'auni na elasticity na kayan roba.

- Gwajin Matsi:Gwajin matsawa yana auna yadda abu ke aiki a ƙarƙashin nauyi mai nauyi da dawowarsa.

- Gwajin Tauri:Gwajin taurin yana auna juriyar abun zuwa ciki.

- Gwajin tsufa:Gwajin tsufa yana kwatanta lalata muhalli na dogon lokaci.

- Gwajin Juriya da Hawaye:Gwajin Juriya na Hawaye yana ƙididdige yadda kayan ke yin tsayayya da haɓakar laƙabi ko yanke.

- Gwajin Juriya na Chemical:Gwajin Juriya na Chemical yana kimanta aiki akan mai, mai, da kaushi.

- Gwajin Saitin Matsi:Gwajin Saitin Matsi yana bayyana ikon abu don murmurewa bayan ci gaba da nakasa.

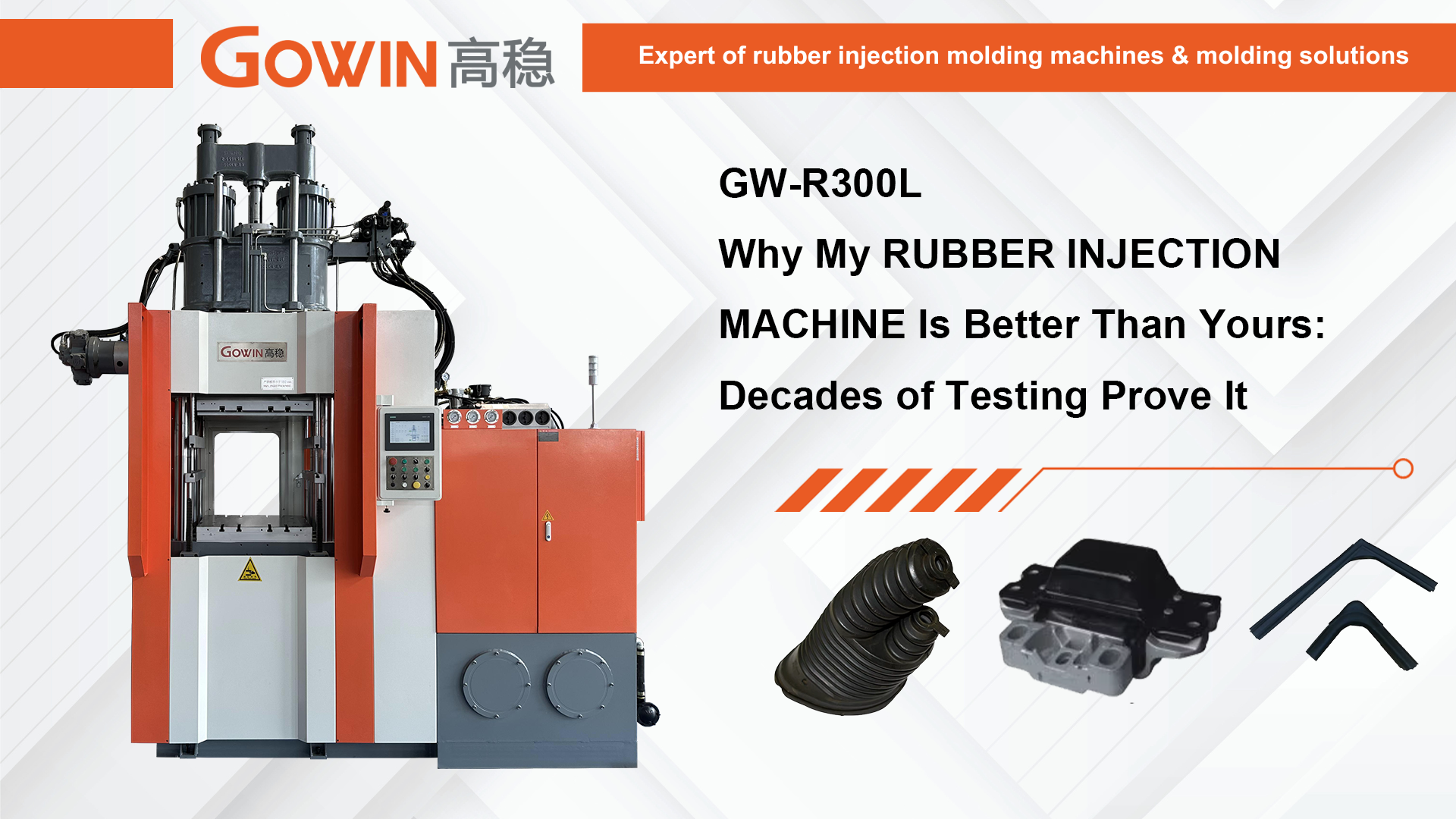

- Gwajin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙara:Waɗannan ba akwati ba ne kawai; su ne ginshiƙan abubuwan da za a iya faɗi, manyan ayyuka. Kuma bayan shekaru 30+ na ƙirƙira labarun ga zuciyar tsarin keɓancewar labarai na roba, zan iya gaya muku wannan babu shakka: ainihin ma'aunin injin ɗin na roba ba kawai takaddun bayanansa ba ne, amma yadda yake ba da damar wuce waɗannan gwaje-gwaje tare da launuka masu tashi, akai-akai, rana da rana. Nawa yayi. Bari in bayyana dalilin da yasa mai yiwuwa naku ya gaza.

Bayan Platen: Inda Gwajin Ya Haɗu da Ayyukan Na'ura

Yawancin masana'antun suna mayar da hankali kawai akan lokutan zagayowar da tonnage. Lokutan zagayowar ba su nufin komai ba idan sassan ku sun kasa gwajin saitin matsawa bayan watanni shida a cikin injin injin. Tonnage ba shi da mahimmanci idan rashin daidaiton matsa lamba yana haifar da saurin karatun taurin kai a cikin aikin samarwa guda ɗaya. Injin nawa an ƙera su tare da fahimtar mahimmanci cewa kowane fanni na aikin su yana tasiri kai tsaye ga waɗannan mahimman sakamakon gwajin ƙasa.

1. Daidaici wanda ya bayyana tensile & elongation: cimma daidaitaccen tsarin kwayar cuta da ake buƙata don madaidaicin madaidaicin ƙarfi a cikin sarrafa zazzabi da allurar allura. Bambance-bambance kaɗan a cikin zafin jiki narke yana da matuƙar tasiri ga haɓakar haɗin giciye - ainihin ainihin kaddarorin tensile. Turi na kai tsaye, tsarin alluran servo na rufaffiyar ba wai kawai da'awar daidaito ba; yana ba da daidaiton narkewar harbi bayan harbi, yana tabbatar da kayan da ke shiga cikin ƙirar yana da ainihin tarihin zafin rana da ake buƙata don buga waɗannan ƙayyadaddun ƙayyadaddun ƙima. Injin gasa da ke dogaro da tsofaffin injinan ruwa kawai ba za su iya daidaita wannan kwanciyar hankali ba, wanda ke haifar da bambance-bambancen tsari-zuwa-tsalle wanda ke kashe daidaiton gwajin ku - da kuma sunan ku tare da masana'antun gyare-gyaren roba waɗanda ke ba da mahimman alluran gyare-gyaren masana'antar kera motoci.

2. The Compression & Compression Set Imperative: Yi tunanin roba matsawa gyare-gyaren inji shi ne kawai game da wadannan kaddarorin? Ka sake tunani. Injunan gyare-gyaren roba na zamani masu inganci, kamar nawa, suna cimma kaddarorin matsawa da ke adawa da gyare-gyaren matsawa na gargajiya, amma tare da ingantaccen inganci da iyawar lissafi mai rikitarwa. Sirrin? Ikon rashin jurewa akan ƙarfin matsewa da bayanan bayanan matsi na allura. Ƙarfin matsawa mara daidaituwa yana kaiwa zuwa walƙiya, wanda ke canza ingantacciyar juzu'i na matsi na ɓangaren yayin gwaji. Rashin kulawar matsa lamba a lokacin allura da matakan warkewa yana haifar da damuwa na ciki da rashin cikar ɓarna - manyan masu laifi a bayan matsananciyar bala'i saitin gazawar. Na'urara ta ainihin lokacin, sarrafa matsi mai daidaitawa da kuma ja-gorancin faranti na masana'antu suna ba da garantin rarraba matsa lamba iri ɗaya. Wannan yana fassara kai tsaye zuwa sassan da ke damfara da tsinkaya kuma suna murmurewa kamar yadda aka kayyade, batch bayan tsari, mai mahimmanci ga hatimi a cikin haɓakar haɓakar kayan aikin roba na kera motoci.

3. Tauri: Ba kawai Tsarin Halittu ba: Kun ƙididdige wani abu 70 Shore A. Me yasa sassan suka bambanta daga 68 zuwa 72 a fadin mold, ko mafi muni, harbi-zuwa-harbi? Rashin daidaiton tarwatsewar na'urori, rashin daidaituwar ɓarna saboda ƙarancin zafin jiki a cikin rami, ko aljihunan iska da aka kama su ne ɓoyayyun abubuwan da injin ke haifar da shi. Injin nawa yana fama da wannan da:

Yankunan Zazzabi Madaidaicin Madaidaici: sarrafawa mai zaman kansa, tare da ƙaramar overshoot/maƙarƙashiya, yana tabbatar da canja wurin zafi iri ɗaya a duk faɗin ƙirar ƙira.

Advanced Screw Design & Mixing: An ƙera shi don roba mai kama da juna da tarwatsewar filler kafin allura, yana kawar da tabo mai laushi.

Ƙarfin Gyaran Vacuum (Zaɓi amma Mahimmanci): Daidaitawa akan yawancin ƙira na, yana cire iska da ƙarfi daga cikin rami, yana hana ɓarna da lahani na saman da ke karkatar da karatun taurin. Shin daidaitaccen injin ɗinku na roba na siliki na iya yin iƙirarin iko iri ɗaya akan waɗannan abubuwan?

4. Cin nasara da tsufa, Hawaye, & Juriya na sinadarai: Dogon Wasan: Waɗannan gwaje-gwajen suna fallasa raunin da aka gina a cikin ɓangaren yayin gyare-gyare. Ƙarƙashin magani saboda rashin kwanciyar hankali kula da zafin jiki? Yi tsammanin rashin juriyar tsufa da juriya na sinadarai. Wuraren ciki ko yawan damuwa daga kwararar tashin hankali? Kiss juriya da hawaye. Ciwon kai daga yanayin zafi mai yawa ko lokutan riƙewa? Barci yana shiga, ya kasa yin gwaji da yawa. Ikon rufe madauki na inji na akan kowane ma'aunin zafi (ganga, bututun ƙarfe, mai gudu mai zafi, farantin) da bayanin martabar allura (gudu, matsa lamba, matsayi) yana tabbatar da daidai adadin kuzarin da aka isar don daidai lokacin. Wannan madaidaicin vulcanization ba zai yuwu ba ga sassan da aka ƙaddara don yanayi mai tsauri - tunanin samfuran ƙirar waya na roba a cikin fakitin baturi EV ko hatimi a sarrafa sinadarai. Bambanci ne tsakanin sashin da ke tafiya ta tsawon sa'o'i 1000 na tsufa na zafi da wanda ke fashe a 500.

5. Gina don Niƙa: Amintaccen ma'aunin Gwaji shima: Na'urar da ta fi dacewa ba ta da amfani idan tana ƙasa don kulawa kowane mako. Downtime yana kashe riba kuma sojoji sun hanzarta samarwa, babu makawa suna lalata inganci da sakamakon gwaji. Shekaru talatin a wannan fannin sun koya mani inda ake yanke sasanninta. Injina na suna amfani da ƙima, abubuwan da aka samo asali na duniya musamman waɗanda aka zaɓa musamman don juriya a cikin yanayin gyare-gyaren roba. Gine-gine mai nauyi, ingantaccen tsarin sarrafa zafi, da wuraren sabis masu isa ba abubuwan jin daɗi ba ne; abubuwan bukatu ne don kiyaye daidaitattun ƙa'idodin Rubber Molding da Rubber Material Testing Protocol kowace shekara. Wannan dogaro mai dorewa kai tsaye yana fassara zuwa barga, fitarwar samarwa wanda za'a iya faɗi wanda ya dace da buƙatun na lokaci-lokaci na kasuwar kayan haɗin roba.

Me yasa "CE Certification Rubber Vulcanizing Press Machinery" Ba Kawai Sitika bane (Kuma Me yasa Nawa Excels)

Takaddun shaida ta CE ta roba vulcanizing injinan jarida shine tushen doka da ake buƙata don kasuwar EU, wanda ke nuna yarda da mahimmancin lafiya, aminci, da umarnin kare muhalli. Amma kyawun gaske ya wuce yarda kawai. Injina na suna ɗaukar ruhin CE ta hanyar:

Amintaccen Tsari ta Ƙira: Bayan tsaro, yi tunanin gazawar da'irori na hydraulic, kariya mai yawa na zafi wanda aka haɗa a matakin tsarin, da tsarin taimako na matsin lamba da aka ƙera tare da sakewa. Ba a kulle tsaro; an ƙera shi a ciki. Wannan yana kare ma'aikatan ku kuma yana tabbatar da samarwa mara yankewa.

Ƙarfafa Ƙarfafa Ƙarfafa Ƙarfafawa: CE yana tura ingantaccen aiki; injina na jagoranta. Tsarin hydraulic mai sabuntawa (inda ya dace), ingantattun ingantattun injunan servo, da sarrafa zafin zafi na hankali suna rage tsadar aiki idan aka kwatanta da tsofaffi, masu fafatawa da kuzari. Wannan ba wai kawai launin kore ba ne; yana da gagarumin fa'ida a kasuwa a yau.

Haɗin Sarrafa hayaƙi: An ƙirƙira tare da musaya ɗin cire hayaki na zaɓi da dacewa tare da tsarin sanyaya rufaffiyar madauki, yin biyayya da ƙa'idodin muhalli masu tsauri kai tsaye.

Gasar Gasa: Yana cikin Sakamako

Lokacin da kuka zaɓi na'urar yin gyare-gyaren roba na, ba kawai kuna siyan ƙarfe da na'urorin lantarki ba. Kuna saka hannun jari a tsarin da aka ƙera daga ƙasa har ya zama babban mai ba da inganci. Kuna saya:

Ƙimar da ba ta dace ba: Rage tarkace, rage sake yin aiki, ƙaddamar da bincike ba tare da wahala ba. Buga juzu'in ku, saitin matsawa, tauri, da kowane takamaiman takamaiman lokaci, kowane lokaci guda.

Tattalin Arziki: Madaidaicin sarrafa harbi da ɗan guntu (godiya ga babban iko da vacuum na zaɓi) kai tsaye yana inganta layin ƙasa. Ingantacciyar filastik yana rage tarihin zafi mai ƙarfi, adana kayan abu.

Gudun zuwa Kasuwa: Dogaro da daidaito yana nufin ƙarancin samarwa da kuma saurin cancantar sabbin kayan aiki da kayan aiki don buƙatar aikace-aikace kamar ayyukan masana'antar kera motoci na allura.

Tabbatar da gaba: An ƙirƙira don daidaitawa - sarrafa komai daga buƙatar mahaɗan FKM don sararin samaniya zuwa silicone mai daraja na likita (aikin na'urar gyare-gyaren siliki na roba musamman na musamman), zuwa EPDM mai girma don mota. Shirye don haɗawa ta atomatik.

Aminci na Hankali: Goyan bayan ƙwarewar masana'antu mai zurfi da goyan bayan da aka kafa a cikin shekaru 30+, ba kawai littafin tallace-tallace ba. Mun fahimci gwaje-gwajen da kuke fuskanta saboda mun ƙirƙira injuna don taimaka muku a cikin su.

Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙaƙwalwar Kaya

A cikin duniya mai girma na gyare-gyaren roba, musamman samar da ainihin madaidaicin kayan haɗin gwal na roba ko samar da samfuran ƙirar waya mai mahimmancin manufa, daidaitaccen aikin gwajin ba na zaɓi ba ne; yana wanzuwa. Kuna iya samun mafi kyawun fili da ƙirar ƙira, amma idan injin ku ya gabatar da sauye-sauye, rashin kwanciyar hankali, ko rashin daidaituwa, zaku gaza. Za ku fuskanci ƙiyayya mai tsada. Za ku rasa kwangila.

Injina na shine ƙarshen shekaru talatin na sauraro, koyo, da hanyoyin injiniya don magance ainihin matsalolin da ake fuskanta a filin samarwa da kuma a cikin dakin gwaji. An gina su don zama mafi aminci, daidaici, kuma daidaitattun abokan tarayya a cikin neman sassan roba mara lahani. Wannan ba tallan tallace-tallace ba ne; babban sakamako ne na falsafar na'ura da aka samo asali a cikin tushen kimiyyar Rubber Molding da Gwajin Kayayyakin Rubber.

Don haka, lokacin da kake tambaya, "Me yasa INJECTION NA RUBBER ta fi naka?" Amsar ita ce mai sauƙi: Domin mine an ƙera shi don tabbatar da cewa sassan ku sun ci jarrabawar. Kowane gwaji. Kowace lokaci. Ashe ba abin da yake da muhimmanci ba ne? Bari muyi magana akan yadda injina zai zama tushen ingantaccen labarin nasarar ku.

Lokacin aikawa: Agusta-22-2025