Masana'antar kera motoci suna ci gaba da haɓakawa, tare da haɓaka haɓaka kayan haɓakawa da hanyoyin masana'antu. Ɗaya daga cikin mahimman abubuwan da ke faruwa a cikin 'yan shekarun nan shine ƙara aikace-aikacen yin gyare-gyaren roba a cikin samar da kayan aikin mota. Wannan dabarar tana ba da fa'idodi masu yawa, gami da daidaito, inganci, da ikon sarrafa ƙira masu sarƙaƙƙiya.

Ci gaba a cikin Gyaran allurar Rubber

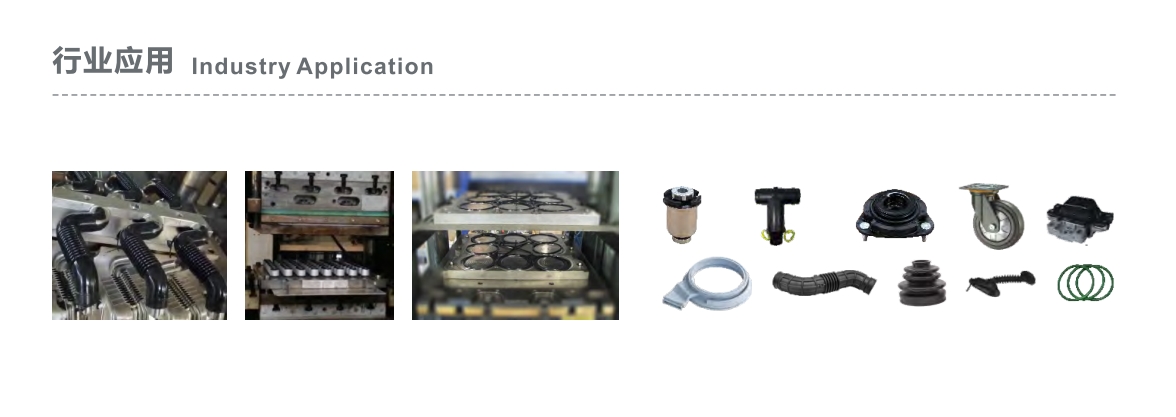

Yin gyare-gyaren gyare-gyaren roba, wani tsari da ke ƙera robar da ba a warkewa ba ta hanyar allura shi a cikin wani ƙarfe, ya zama hanyar da aka fi so don kera sassan motoci daban-daban saboda daidaito da ingancinsa. Ba kamar hanyoyin gyare-gyare na al'ada ba, gyare-gyaren allura na iya samar da sassa tare da lokutan sake zagayowar sauri da daidaituwa mafi girma, yana sa ya dace don samar da girma.

Maɓallin Aikace-aikace a cikin Sashin Mota

1. Seals and Gasket: Ana amfani da allurar roba da yawa don samar da hatimi da gaskets, waɗanda ke da mahimmanci don hana yaɗuwa da kuma tabbatar da amincin tsarin daban-daban a cikin abin hawa. Dole ne waɗannan abubuwan haɗin gwiwa su yi tsayayya da babban matsi da yanayin zafi, suna yin tsayin daka da daidaiton da ake bayarwa ta hanyar gyare-gyaren allura mai mahimmanci.

2. Adaftar Drive Beam (ADB) Lens Optics: A NPE 2024, Krauss-Maffei ya nuna amfani da Dow's SILASTIC ™ MS-5002 Moldable Silicone a cikin samar da ruwan tabarau na ADB don motoci. Wannan ƙirƙira tana ba da ƙarin haske game da damar yin gyare-gyaren roba na roba don ɗaukar ƙira da kayayyaki masu rikitarwa tare da takamaiman buƙatun aiki.

3. Hatimin Haɗi: Wani sanannen aikace-aikacen shine samar da hatimin haɗin haɗin ta amfani da Dow XIAMETER ™ RBL-2004-50 LSR. Waɗannan hatimai suna da mahimmanci don tabbatar da ingantattun hanyoyin haɗin lantarki a cikin abubuwan hawa, suna nuna haɓakar gyare-gyaren allurar roba a cikin samar da sassa masu ƙarfi mai ƙarfi da ƙarancin matsawa.

4. Masu Rarraba Batir Don Motocin Lantarki (EVs): Yayin da masana'antar kera ke motsawa zuwa motocin lantarki, ana samun karuwar buƙatun kayan haɗin roba na musamman kamar masu rarraba baturi. Waɗannan sassan suna buƙatar kayan da ke ba da haske mai girma da lokutan warkewa da sauri, halayen da suka dace da hanyoyin gyaran gyare-gyare na roba.

Fa'idodi da Gabatarwa

Yin amfani da alluran roba a masana'antar kera motoci yana ba da fa'idodi da yawa:

- Matsakaicin daidaito da daidaito: Tsarin yana tabbatar da cewa kowane bangare ya hadu da tsauraran matakan inganci, rage yuwuwar lahani.

- Inganci: Saurin zagayowar lokutan suna fassara zuwa mafi girman ƙimar samarwa, mai mahimmanci don biyan buƙatun masana'antar kera motoci.

- Ƙarfafawa: Ƙarfin ƙirƙira nau'ikan roba daban-daban, gami da manyan elastomers, yana ba da damar samar da abubuwa da yawa.

Yayin da masana'antar kera motoci ke ci gaba da haɓakawa, ana sa ran aikin yin gyare-gyaren roba zai yi girma. Ƙirƙirar sabbin kayayyaki da fasaha za su iya ƙara haɓaka ƙarfin wannan tsarin masana'antu, tare da tallafawa samar da ingantattun abubuwan kera motoci.

Lokacin aikawa: Mayu-27-2024