Gabatarwa

Filastik da allura gyare-gyaren roba sun mamaye matsayi mai mahimmanci a masana'antar masana'antar zamani. Ko samfuran roba ne na yau da kullun a rayuwar yau da kullun, ko samfuran roba da ake amfani da su sosai a fagen masana'antu, fasahar gyare-gyaren allura tana taka muhimmiyar rawa. Wannan labarin yana da nufin zurfafa cikin bambance-bambance tsakanin filastik da gyare-gyaren allura don taimakawa masu karatu su fahimci waɗannan mahimman hanyoyin masana'antu guda biyu.

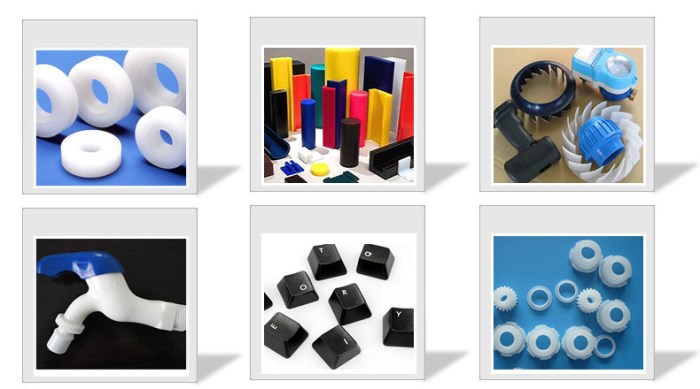

Yin gyare-gyaren filastik wani tsari ne wanda ake ɗora robobin da aka narkar da shi a cikin wani nau'i, wanda aka sanyaya kuma yana da ƙarfi don samar da takamaiman samfurin. Bisa kididdigar da aka yi, adadin kayayyakin robobi da ake samarwa ta hanyar yin allurar filastik a duniya suna da yawa a kowace shekara. Misali, abubuwa da yawa na robobi da masu kera motoci ke amfani da su, irin su sassan ciki, na’urar bumpers, da sauransu, ana yin su ne ta hanyar yin allurar filastik.

Rubber gyare-gyaren allurashine allurar kayan roba a cikin kwandon, bayan vulcanization da sauran hanyoyin, don yin samfuran roba iri-iri. Hakanan ana amfani da samfuran roba a cikin motoci, injina, kayan lantarki da sauran fannoni. Misali, tayoyin mota, hatimi, da sauransu, samfurori ne na yau da kullun na allurar roba.

Muhimmancin hanyoyin gyaran allura guda biyu ba wai kawai za su iya samar da samfuran inganci tare da sifofi masu rikitarwa ba, har ma suna iya tabbatar da daidaito da ingancin samfuran. Ta hanyar sarrafa daidaitattun sigogi kamar zafin jiki, matsa lamba da lokaci yayin allura, ana iya samar da samfuran tare da daidaiton girman girma da ingancin saman ƙasa. A lokaci guda, waɗannan matakai guda biyu kuma suna da fa'ida na ingantaccen samarwa da ƙarancin farashi, kuma suna iya biyan buƙatun samar da manyan kayayyaki.

Bayanin gyare-gyaren allurar filastik

(1) tsari tsari da kwarara

Tsarin tsari na yin gyare-gyaren filastik shine ƙara granular ko powdered filastik albarkatun kasa zuwa hopper na allura inji, da albarkatun kasa suna mai tsanani da kuma narke a cikin wani gudana jihar, kore ta dunƙule ko fistan na allura inji, ta bututun ƙarfe da zub da tsarin na mold a cikin mold rami, da sanyaya da kuma karfafa a cikin mold rami.

Ƙayyadadden tsari ya haɗa da matakai masu zuwa: Na farko, shirye-shiryen kayan aiki, bisa ga bukatun samfurin don zaɓar kayan albarkatun filastik da suka dace, irin su polystyrene na kowa, polyethylene, polypropylene da sauransu. Waɗannan albarkatun ƙasa yawanci suna da halaye daban-daban na aiki, kamar ƙarfi, ƙarfi, juriya na zafi, da sauransu, don saduwa da buƙatun samfuran daban-daban. Sa'an nan kuma an ƙara danyen abu zuwa injin allura don dumama da narkewa, a cikin wannan tsari, wajibi ne don sarrafa zafin zafin jiki sosai, gabaɗaya, albarkatun albarkatun filastik daban-daban suna da nau'ikan zafin jiki na narkewa daban-daban. Misali, zafin da ke narkewa na polyethylene yawanci yana tsakanin 120 ° C -140 ° C, yayin da zafin narkewar polystyrene ya kai 180 ° C -220 ° C.

Lokacin da danyen kayan ya narke kuma yana gudana, ana tura shi ta dunƙule ko piston na injin allura a cikin rami mai ƙyalƙyali ta cikin bututun ƙarfe da tsarin zubar da ƙura. A cikin wannan tsari, matsa lamba na allura shine maɓalli mai mahimmanci, wanda ke buƙatar zama babba don shawo kan juriya na narke yayin da yake gudana kuma tabbatar da cewa narke zai iya cika rami na mold. Gabaɗaya, matsa lamba na allura na iya kasancewa tsakanin dubun zuwa ɗaruruwan mpa.

A ƙarshe, a cikin mataki na sanyaya, filastik yana sanyaya kuma yana ƙarfafawa a cikin kogon ƙirar ta hanyar tsarin sanyaya na mold. Tsawon lokacin sanyaya ya dogara da nau'in filastik, kauri na samfurin da sauran dalilai. Gabaɗaya magana, lokacin sanyi na samfuran sirara ya fi guntu, wanda zai iya zama tsakanin dubun daƙiƙai da ƴan mintuna; Za a tsawaita lokacin sanyi na samfurori masu kauri daidai da haka.

(2) Halaye da fa'idodi

Yin gyare-gyaren filastik yana da halaye da fa'idodi da yawa. Na farko, zai iya yin hadaddun siffofi. Saboda robobin yana da ruwa mai kyau a cikin narkakken yanayi, ana iya cika shi da guraben guraben gyare-gyaren gyare-gyare, ta yadda za a samar da samfuran filastik masu siffa daban-daban, kamar samfuran da ke da kogon ciki da kuma juzu'i.

Abu na biyu, daidaito ya fi girma. Ta hanyar sarrafa daidaitattun sigogi kamar zafin jiki, matsa lamba da lokaci yayin aikin allura, ana iya samar da samfura masu girman girman girma, kuma ana iya sarrafa juriya mai girma tsakanin ƴan zuwa ɗimbin wayoyi. Misali, wasu madaidaicin harsashi na samfur na lantarki na iya cimma buƙatun daidaito mai girma ta hanyar yin gyare-gyaren filastik.

Bugu da kari, filastik allura molds ne daban-daban, dace da iri-iri na sarrafa kasuwanci siffofin. Za'a iya tsara nau'ikan allura daban-daban don samfuran daban-daban gwargwadon siffar su, girman su da buƙatun aikin su. Haka kuma, allura molds za a iya taro-samar, tare da high samar yadda ya dace, kuma sun dace da daban-daban nau'i na sarrafa ciniki, kamar OEM (ainihin kayan aiki manufacturer) da ODM (na asali zane manufacturer).

A lokaci guda, gyare-gyaren allurar filastik yana da nau'i mai yawa na daidaitawa. Ana iya amfani da ita don kera nau'ikan samfuran filastik, tun daga kayan yau da kullun kamar kayan tebur, kayan wasan yara, kayan masana'antu kamar shingen lantarki, sassan mota da sauransu. Bisa kididdigar da aka yi, kusan kashi 70% na kayayyakin robobi na duniya ana yin su ne ta hanyar yin allura.

Bayanin injin yin gyare-gyaren roba na roba

(1) tsari tsari da kwarara

Injin gyare-gyaren alluran robawani nau'i ne na fasaha na sarrafa kayan aiki wanda ke aikawa da kayan aiki zuwa cikin tsari ta hanyar babban aikin roba, kuma bayan wani matsa lamba da zafin jiki, albarkatun robar suna samar da siffar da ake bukata a cikin ƙirar.

Takamammen tsari shine kamar haka:

Ayyukan shirye-shirye: ciki har da duban kayan albarkatun roba, bushewa, preheating da sauran ayyuka, da ƙirar ƙira, masana'anta da lalata. Nuna kayan albarkatun roba yana da mahimmanci don tabbatar da cewa inganci da aikin albarkatun ƙasa sun cika buƙatun samfuran. Misali, ga wasu samfuran roba masu inganci, kamar tayoyin mota, hatimi, da sauransu, wajibi ne a zaɓi ɗanyen roba masu inganci don tabbatar da ƙarfi, juriya da juriya na samfuran. A cikin tsarin bushewa da zafin rana, ya kamata a kula da zafin jiki da lokaci sosai don guje wa bushewa da yawa ko rashin isasshen preheating na albarkatun roba. Ana buƙatar ƙira da ƙirar ƙirar ƙira a hankali bisa ga sifa, girman da buƙatun aikin don tabbatar da daidaito da ingancin ƙirar.

Samar da kayan aiki: Ana ƙara busassun busassun roba a cikin mai fitar da roba, kuma an riga an riga an magance kayan ta hanyar wasu matakai kamar dumama da fitarwa. A cikin wannan tsari, aiki da saitunan saiti na robar extruder suna da matukar muhimmanci. Alal misali, zafin jiki na extruder, dunƙule gudu da sauran sigogi za su shafi kai tsaye tasiri plasticizing da ingancin kayan roba. Gabaɗaya, yawan zafin jiki na extruder na iya kasancewa tsakanin 100 ° C da 150 ° C, kuma saurin dunƙule na iya zama tsakanin dubun zuwa ɗaruruwan juyi a minti ɗaya, kuma takamaiman sigogi yakamata a daidaita su gwargwadon nau'in da buƙatun aikin kayan aikin roba.

Molding: Ana ciyar da kayan roba da aka riga aka yi wa magani a cikin ƙirar ta injin allura don aikin gyare-gyare. A wannan lokacin, ana buƙatar haɗa wani matsa lamba da zafin jiki don sanya albarkatun robar su zama samfurin da ake so da girman da ake so. A matsa lamba da kuma yawan zafin jiki a cikin gyare-gyare tsari ne key sigogi, da matsa lamba iya kullum zama tsakanin dubun zuwa daruruwan mpa, da kuma yawan zafin jiki na iya zama tsakanin 150 ° C da 200 ° C. Daban-daban roba kayayyakin da daban-daban bukatun ga matsa lamba da zafin jiki, misali, ga wasu manyan roba kayayyakin, kamar roba drum fuska, gada girgiza absorbers, da dai sauransu, mafi girma matsa lamba da kuma zafin jiki da ake bukata don tabbatar da ingancin kayayyakin m.

Rushewar matsawa: Bayan an kammala gyaran gyare-gyare, ya zama dole don kwantar da hankali da zubar da hankali don cire samfuran roba daga ƙirar. Ya kamata a aiwatar da tsarin sanyaya sannu a hankali don guje wa lalacewa ko fashe samfuran saboda saurin canjin zafin jiki. Yi hankali lokacin tarwatsawa don guje wa lalata samfurin.

(2) Halaye da fa'idodi

Ƙarfin samarwa guda ɗaya: ƙarfin samarwa guda ɗaya na injin gyare-gyaren roba yana gabaɗaya tsakanin dubun gram da kilogiram da yawa, wanda ke inganta haɓakar samfuran da aka gama.

Babban daidaiton samfur: Injin gyare-gyaren roba na roba na iya sarrafa daidaitaccen zafin jiki, matsa lamba da sauran sigogin kayan yayin aiwatar da gyare-gyaren, don haka inganta daidaiton samfurin sosai.

Short gyare-gyaren sake zagayowar: Saboda roba gyare-gyaren gyare-gyare na iya samar da mahara kayayyakin a lokaci guda, da kuma samar iya aiki ne babba, da gyare-gyaren sake zagayowar ne in mun gwada da gajere. Misali, wajen kera wasu sassa na mota, yin amfani da tsarin gyaran gyare-gyaren roba na iya inganta ingancin samarwa da kuma rage tsawon lokacin samarwa.

Babban ingancin samfurin da aka gama: gyare-gyaren roba na roba zai iya rage samfurin saboda rashin daidaituwa, kumfa da sauran matsalolin, don haka ingancin samfurin ya inganta sosai. Misali, hatimin mota da aka samar ta hanyar yin gyare-gyaren alluran roba suna da kyakkyawan hatimi da juriya, wanda zai iya haɓaka aiki da rayuwar sabis na motoci yadda ya kamata.

Bambanci tsakanin roba da roba gyare-gyaren allura

(1) Bambance-bambance a cikin halayen albarkatun kasa

Kayan albarkatun filastik yawanci thermoplastic ko resin thermosetting, wanda ke da tauri da ƙarfi, kuma nau'ikan albarkatun filastik daban-daban suna da halaye daban-daban na aiki, kamar ƙarfi, ƙarfi, juriya na zafi da sauransu. Alal misali, polyethylene yana da kyakkyawan juriya na sinadarai da wutar lantarki, amma ƙarfinsa da juriya na zafi suna da ƙananan ƙananan; Polystyrene yana da babban nuna gaskiya da tauri, amma yana da karye. Waɗannan halaye sun ƙayyade cewa filastik yana buƙatar takamaiman zafin jiki da kewayon matsa lamba yayin gyaran allura don tabbatar da cewa albarkatun ƙasa na iya narke gabaɗaya kuma ya cika rami na gyambo.

Kayan albarkatun kasa na roba shine roba na halitta ko roba na roba, wanda ke da babban elasticity da sassauci. Rubber yawanci mai laushi ne kuma mai sauƙin lalacewa a cikin yanayin da ba a taɓa gani ba, yayin da yake da ƙarfi da ƙarfi kuma yana juriya bayan vulcanization. Abubuwan na roba na roba suna sa ya zama dole don la'akari da ƙimar raguwa da juriya na kayan a cikin tsarin gyare-gyaren allura don tabbatar da daidaiton girma da daidaiton siffar samfurin. Alal misali, lokacin zayyana nau'in nau'in roba don samfuran roba, ya zama dole a la'akari da cewa raguwar adadin roba yana da girma, yawanci tsakanin 1% -5%, yayin da raguwar ƙimar filastik gabaɗaya tsakanin 0.5% da 2%.

(2) Bambance-bambance a cikin sigogin tsari

Dangane da yanayin zafi, yawan zafin jiki na allurar filastik yakan fi girma, kuma albarkatun albarkatun filastik daban-daban suna da kewayon zafin narkewa daban-daban. Alal misali, da narkewa zafin jiki na polyethylene yawanci tsakanin 120 ° C da kuma 140 ° C, da kuma narkewa zafin jiki na polystyrene ne game da 180 ° C da kuma 220 ° C. The zafin jiki na roba allura gyare-gyare ne in mun gwada da low, kullum tsakanin 100 ° C da 200 ° C, da kuma takamaiman zafin jiki ya dogara da nau'in da aikin da bukatun na rubber. Misali, zafin vulcanization na roba na halitta yawanci yana tsakanin 140 ° C da 160 ° C, kuma zafin vulcanization na roba roba na iya bambanta.

Dangane da matsa lamba, gyaran gyare-gyaren filastik yana buƙatar babban ƙarfin allura, gabaɗaya tsakanin dubun zuwa ɗaruruwan mpa, don shawo kan juriya na narkewa a cikin tsarin gudana da kuma tabbatar da cewa narke zai iya cika rami na mold. Matsakaicin gyaran gyare-gyaren roba yana da ɗan ƙaramin ƙarfi, gabaɗaya tsakanin dubun zuwa ɗaruruwan mpa, amma ga wasu manyan samfuran roba, ana iya buƙatar matsa lamba mafi girma. Misali, lokacin da ake samar da manyan kayayyakin roba irin su fuskar bangon roba da na'urar bugu ga gada, ana buƙatar matsa lamba mai ƙarfi don tabbatar da ingancin samfuran.

(3) Bambance-bambance a cikin halayen samfur

Dangane da siffa, gyare-gyaren allura na filastik na iya samar da kayayyaki iri-iri tare da sifofi masu rikitarwa, kamar samfuran filastik tare da kogo na ciki, tsarin baya, da sauransu.

Dangane da daidaito, gyare-gyaren allura na filastik na iya samar da samfura tare da daidaiton girman girma, kuma ana iya sarrafa juriyar juzu'i tsakanin ƴan wayoyi da yawa na wayoyi. Daidaiton samfuran gyare-gyaren alluran roba yana da ƙarancin ƙarancin ƙarfi, amma ga wasu samfuran roba masu inganci, kamar hatimin mota, da sauransu, yana iya cimma buƙatun daidaito mafi girma.

Dangane da amfani, ana amfani da kayayyakin robobi sosai a cikin buƙatun yau da kullun, samfuran masana'antu da sauran fannoni, kamar kayan tebur, kayan wasan yara, harsashi na lantarki, sassan mota da sauransu. Ana amfani da samfuran roba a cikin motoci, injina, na'urorin lantarki da sauran fannoni, kamar taya, hatimi, na'urar buguwa da sauransu.

Kammalawa

Akwai bayyane bambance-bambance tsakanin filastik da gyare-gyaren allura na roba a cikin halayen albarkatun ƙasa, sigogin tsari da halayen samfur.

Daga mahangar halaye na kayan albarkatun ƙasa, kayan albarkatun filastik yawanci thermoplastic ko resins na thermosetting, waɗanda ke da ƙarfi da ƙarfi, kuma robobi daban-daban suna da kaddarorin daban-daban. Kayan albarkatun kasa na roba shine roba na halitta ko roba na roba, wanda ke da babban elasticity da sassauci.

Dangane da sigogin tsari, zafin jiki na allurar filastik ya fi girma, kewayon zafin narke na robobi daban-daban ya bambanta, kuma matsa lamba na allura ya fi girma don tabbatar da cewa narke yana cike da rami. Zazzaɓin gyare-gyaren roba yana da ɗan ƙaramin ƙarfi, matsa lamba kuma yana da ƙasa kaɗan, amma manyan samfuran roba na iya buƙatar matsa lamba mafi girma.

Halayen samfur, gyare-gyaren allura na filastik na iya kera samfuran sifa masu rikitarwa, daidaitattun daidaito, ana amfani da su sosai a rayuwar yau da kullun da filayen masana'antu. Saboda girman elasticity, samfuran roba galibi suna da sauƙi a siffa kuma suna da ƙarancin daidaito, amma samfuran roba masu inganci kuma suna iya biyan madaidaicin buƙatun, galibi ana amfani da su a cikin motoci, injina, lantarki da sauran fannoni.

Waɗannan hanyoyin gyaran allura guda biyu suna da mahimmanci ga masana'antu masu alaƙa. A cikin masana'antar samfuran filastik, gyare-gyaren allura na filastik yana da inganci, ƙarancin farashi, yana iya biyan buƙatun samarwa da yawa, kuma yana samar da kayayyaki iri-iri don fannoni daban-daban. A cikin masana'antar samfuran roba, ƙarfin samarwa guda ɗaya na gyare-gyaren allura na roba yana da girma, daidaiton samfuran yana da girma, sake zagayowar gyare-gyaren gajere ne, kuma samfurin da aka gama yana da inganci, wanda ke ba da mahimman sassa da hatimi da sauran samfuran don mota, injina da sauran masana'antu, yana tabbatar da ingantaccen ci gaban waɗannan masana'antu. A takaice dai, gyare-gyaren filastik da roba suna taka rawar da ba za a iya maye gurbinsu ba a masana'antar zamani, kuma halayensu da fa'idodin su kuma suna ba da tallafi mai ƙarfi don haɓaka masana'antu daban-daban.

Lokacin aikawa: Nuwamba-08-2024